Healthy food technology fruit and vegetable slices after deep-frying to keep broken - low temperature vacuum frying machine.

Compared with atmospheric frying technology, vacuum frying can reduce the oxidation of nutrients and oil due to its low oxygen and low temperature processing conditions. Maintain the natural color and flavor of the product; Reduce acrylamide production; Reduce nutrient loss and oil content.

Can be widely used in: vegetable slices, fruit slices fried, such as okra, carrot strips, mushrooms, banana slices, jackfruit, etc.

I. Working principle:

Fruit and vegetable crisp is made of fresh fruit and vegetable as the main raw material, edible vegetable oil as the heating medium, and low-temperature vacuum frying (VF) and other advanced technologies, which can be rapidly dehydrated in a very short time and dry time to obtain low water content. Fruits and Vegetables Foods are low in oil, crisp but not greasy, retain the original shape, color, aroma and taste of fruits and vegetables, and are rich in vitamins, minerals, fiber and other nutrients. They are low in sugar, salt, fat and fever.

Stainless steel coil heating, rapid heating, constant oil temperature, to ensure product color, aroma, taste and shape.

Two. Applicable food scope:

1). Fruit: such as apple, banana, monkey peach, pineapple, winter date, strawberry, jackfruit and so on.

2). Vegetables: such as carrots, radish, sweet potato, pumpkin, garlic, onion, mushroom, winter melon, okra and so on.

3). Meat food: such as beef, fish, shrimp, octopus and so on.

Three. Processing process:

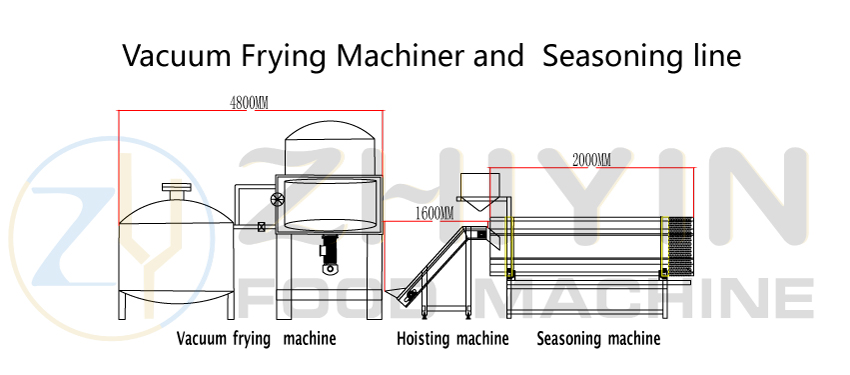

Raw material → screening → cleaning → slicing (cut into sections) → fixation → drainage → vacuum impregnation → quick-freezing → vacuum frying → vacuum deoiling → seasoning → finished product.

Vegetable and fruit slices (diced vegetables) :

1. Clean fruits and vegetables, cut them, wash them, dehydrate them, freeze them (freezing temperature is minus 18 degrees),

2. Do cold processing into the material, each batch of frying time about 40-50 minutes (except seafood),

3. Low temperature frying temperature setting reference 86 degrees -92 degrees.

4. After feeding, the machine sets the temperature and frying time with one key.

5. Crispy after raw fried.

6. Fried vegetable slices can be seasoned.

We are a manufacturer of food machinery.

Our factory can do potato chips processing machinery,frozen french fries making line,french fries frying machine,food frozen machine,vegetable fruit cleaning washing machine,freeze drying machine,Food vacuum frying machine and so on.

Our machines can be customized and we have proven solutions.

The lead time of the production line is about 35 working days.

My whatsup +86 152 4967 4563

So,Attentive readers will find that our domain names show,

Our professional food machinery manufacturing and production.

Frozen French Fries Making Line

potato Chips Making Line

Potato Chips Production Line

Banana Chips Production Line

Snacks Frying Production Line

Vegetable/Fruit Washing Line

Vegetable/Fruit Drying Line

Seafood Thaw Cooking Line

Food freeze drying equipment

Food Puffed Production Line

Food Vacuum Frying Machine

Food Freezing Machine