automatic potato chips production line Frozen French Fries Making Machine-Custom chip line solution

Mechanical capacity customization of automatic frozen potato chips production line, configuration of quick-frozen potato chips production line

For example, potatoes are used as raw materials, and the inside of potatoes contains moisture and starch, so half of the customized production lines make a customized french fries production line plan based on the weight of the raw materials processed. If the finished product weight is used as the reference for the final production capacity, it can also be customized.

Then the French fries/chips have a high water content before frying. After high temperature frying, the water is completely evaporated, and the finished product no longer contains water, so the finished French fries and chips are lighter in weight.

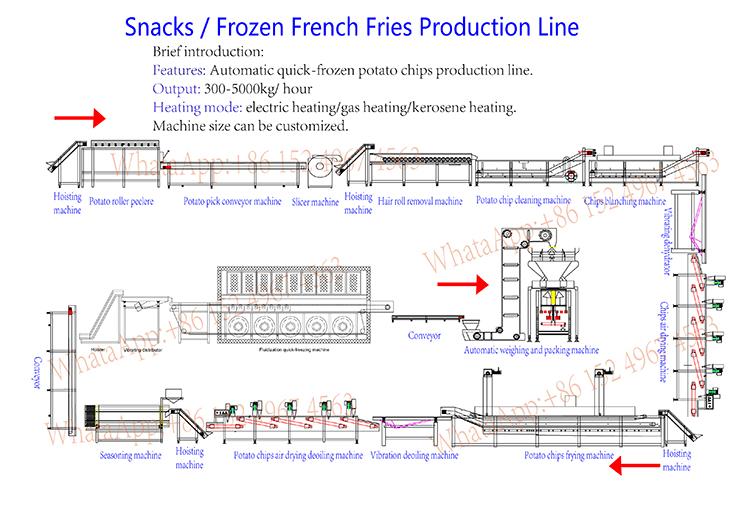

Flow chart of automatic frozen french fries production line:

Question Case 1: Can the expected production capacity of potato chips and French fries be achieved?

A:Our french fries quick-freezing production line can customize the size of each single machine according to your needs, and can meet your production capacity requirements. At the same time, each of our single machine is equipped with a frequency conversion motor, which can adjust the speed independently, so there is no need to worry about the production process. speed.

Case Question 2: What heating methods are used in the blanching machine and the continuous fryer in the process of frying french fries and chips?

A:According to your local heating energy as a reference, if your local electricity bill is relatively high (for example, 0.2 USD/kWh per kWh), do not use electric heating.

The heating method of the blanching machine adopts steam heating, which can maintain the maximum heat source utilization. The heating heat source method of the steam generator can choose gas/natural gas/electricity.

The frying heating method adopts gas pipeline heating, and we have equipped the machine with a complete set of burners.

Case Question 3: Selection of edible oil for frying French fries and potato chips, and the capacity of edible oil input.

A:If you consider the cost for frying, you can choose salad oil/palm oil, soybean oil. The cost of soybean oil is high, so it depends on personal choice.

The input amount of edible oil, the length of each frying machine is different, and the capacity is different, so the input amount of oil is based on the submerged automatic frying machine Internet belt.

Case Question 4: How long is the oil cycled?

A:We will configure oil storage tanks according to different automatic frying, and carry out a storage and circulation of frying edible oil. The process requires more detailed and can be equipped with a frying filter to filter the circulating edible oil well.

Case Question 5: Why is the configuration of the French fries quick-freezer not a traditional tunnel type?

A:The traditional chain tunnel type quick-freezer can only enter the quick-freezer according to the placement state of the product when the material is fed. After the material is fed, the distribution is uneven and there is adhesion. The french fries are extruded and frozen in the tunnel at low temperature.

If the production capacity of the french fries line is too large, the fries will be frozen and discharged by sticking, so the effect is not good.

We have a mature quick-frozen french fries production line solution, which can better solve the existence of such problems and can discharge finished products well, so please do not use the traditional quick-freezing line to compare with our exclusive solution.

We can complete the customization of your needs: the production capacity of the automatic frozen potato chips production line is customized, and the configuration of the quick-frozen potato chips production line

WhatsApp 86 152 4967 4563

Emai: sale@frenchfriesline.com

More Website: www.frenchfriesline.com

Products Advantage

1.Process capacity (finished capacity 100kg/h to 2000kg/h) and work flow can be customized. french frying production line

2. Allequipment are made of SUS304, electrical apparatus element are Schneider brand or CHINT brand.

3. Heating method: Electric heating, Gas heating or Diesel heating (equipped with RIELLO or BALTUR burner), etc.

4. The size of French fries and the thickness of potato chips are adjustable. french fry production line

5. For French fries line, we have special equipment to remove the unqualified fries. french fry production line

6. With special designed fryer, quick heating and energy saving, enabled good performance. french fry production line