-

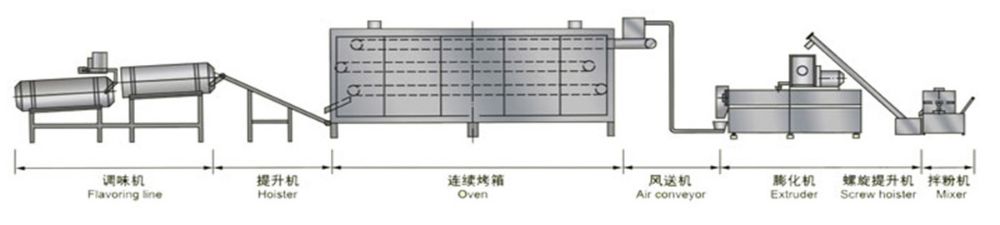

Automatic corn flakes making machine breakfast cereals production line Extruded Cheerios Puffed Cereal Breakfast Machine

Automatic corn flakes making machine breakfast cereals production line Extruded Cheerios Puffed Cereal Breakfast Machine -

Poultry Machinery-braised Chicken Feet Processing Machinery, Chicken Feet Deboning Machine 200kg/hour

Poultry Machinery-braised Chicken Feet Processing Machinery, Chicken Feet Deboning Machine 200kg/hour -

Poultry Slaughtering Line Chicken And Duck Slaughtering, Hair Removal And Plucking Processing Production Line

Poultry Slaughtering Line Chicken And Duck Slaughtering, Hair Removal And Plucking Processing Production Line

Advantages of extruded pet feed production line equipment-Pet Feed Extrusion Machinery Customization

Advantages of extruded pet feed production line equipment:

1. The dog food equipment model has a built-in screw and a longer screw sleeve. The material has a long rotary cutting time, the temperature can be adjusted, and the output torque can be adjusted, so that the material has a high degree of puffing and a smooth surface.

2. Different feeds can be made, this model can make: fresh meat dog food, high protein dog food, grains dog food, pet feed pellets, fishing feed pellets, suspended aquatic feed pellets, sinking fish, shrimp and crabs Feed pellets, etc.

3. The international advanced granulation structure adopts the form of soft knife to realize stepless speed change, and can cut the output material into products of the required length at will, and it is not easy to produce burrs.

4. The design is novel, unique, simple in structure, easy to install, easy to disassemble, and easy to operate.

5. The screw sleeve and screw are made of special wear-resistant and high-temperature-resistant alloy steel material and are heat-treated, which has the advantages of wear resistance and long service life.

6. Equipped with a unique pressure-increasing die device to ensure feed output and quality, and equipped with an electric heating device to improve the feed expansion rate.

7. The main motor adopts high-quality Y series two-phase and three-phase motors to ensure strong power.

8. The speed-adjustable feeding device is more convenient to operate, the feeding is uniform, and the combustion engine is prevented.

9. It is easy to replace the discharge template. If you need different aperture feeds, you only need to replace the required aperture template.